Author:Anita Liu

Even there is a varietie of automatic information transfer systems in the current market, but it is difficult to find one which absolutely satisfies electronic manufacturer’s need. Therefore, the PSI management division started to create its own auto exchange system in the mid of Nov., 2011. The main purpose of the auto exchange system is to reduce the labor cost. On the other hand it not only could increase the working efficiency but also minimize the lead time of the whole production time.

The initial plan are divided into stages below:

1. The paperless environment for technical document.

2. Automatic management of technical document.

3. Automatic comparison between old and new BOM.

4. The EDI automatic BOM structure exam and input system

It took about 3 months from organizing, designing, modifying, testing to practical operation. There were intensive internal discussions and cross division communication. The IT Dept. spent about 2 months over and over again modifying to satisfy end users requirement. Finally, the automatic system was launched in the fourth quarter of 2012. The new auto exchange system could bring such improvement for PSI indeed.

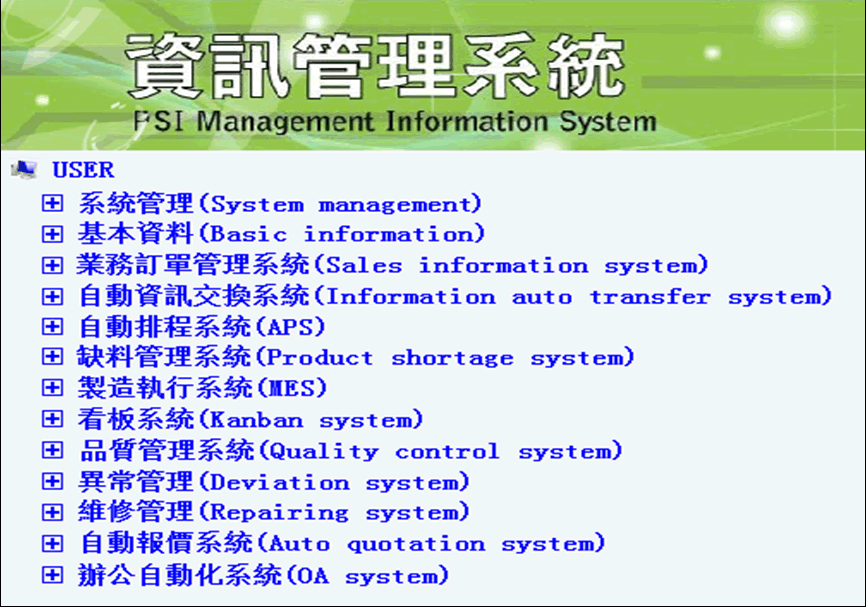

First of all, it was a great achievement for automatic information exchange system to integrate the MIS UI interface. Quality control Dept., Produce control Dept. and other departments all can operate under the same portal interface.

In order to cope with the diverse market demand in the future, the automatic information exchange system keeps certain flexible space to adjust, dealing with the special demand from each customer.

There are still some automatic procedures will be done in the near future, which is to complete the MIS information exchange system. With the help of such powerful system, we all believe that Pronology will provide better quality and more competitive service, create the win-win situation.